Great Tips on Buying Equipment for your Business

Contents

- Combi Ovens

- Dishwashers

- Glasswashers

- Ice Makers

- Installation Instructions

- Microwave Ovens

- Blast Chillers / Blast Freezers

Combi Ovens

What is a combi oven?

Combi ovens combine steam cooking, convection cooking and a combination of the two, hence the name.

Benefits

There are many benefits for the hospitality operator in owning a combi-steam oven:

Improved results

Your food is more flavoursome and there is no cross contamination of flavours

Savings

There are two main areas of savings

Food costs

- Combi-steamer ovens provide a better cooking environment which dramatically reduces food shrinkage during the cooking process. If you are currently cooking in a static or convection oven, your shrinkage on roast beef would be about 30 percent. This means that if you start with 3 kgs of meat your finished product weighs only 2 kgs.

- Now if you are paying $10.00 per kilo for meat the real cost is $15.00 per kilo after cooking.

- Combi-steamer ovens can reduce this shrinkage to as little as 5 to 10 percent depending on how you use the oven. Your savings potential here, on an annual basis, is enormous.

- Wages

- Combi-steamer ovens allow you to prepare weekend food during week, at less costly wage rates. On the weekend you simply require someone to use the regeneration facility to re-heat the food. Potential savings are again enormous.

Better Product

When used correctly, your meats will be more tender, your vegetables more flavoursome and your results generally better.

Standardised performance

If you buy the more expensive programmable combi's one of the great benefits is that you can have standardised results for every meal produced in your kitchen, from executive chef to apprentice or weekend cook.

Re-generation capability

Prepare your weekend meals during the latter part of the working week and use the regeneration facility to reheat these meals, saving your business money on wages without sacrificing food quality.

Occupational Health and Safety Issues

Lifting and carrying large heavy pots of boiling water is a thing of the past with combi's. You can now produce the same food with better results in combi's.

How to size the correct combi oven for your establishment

Just scroll down until you find the appropriate number of covers for your establishment, then across the line to see your choices. Sydney Commercial Kitchens sells all of these models at competitive pricing, Australia wide.

There are 2 types of combi-steam ovens available:

1. Boiler based combi ovens

A steam generator injects the steam directly into the oven chamber. They are available in either gas or electric, though electric is by far the most popular. This style combi is the more expensive of the two.

2. Direct water injection combi steamers

Steam is manufactured by injecting water directly onto the element. The steam is generated in the oven chamber itself.

Generally there are 2 styles of combi ovens in both boiler and direct injection, manual controls and touch screen fully automatic.

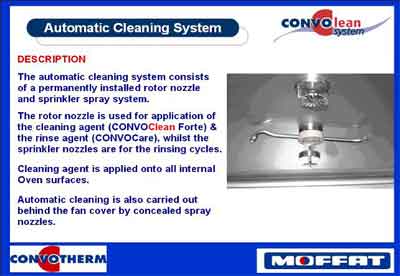

Also available on convotherm combi ovens as an option is the cleaning system. This must be ordered with the combi and cannot be retro fitted.

Dishwashers

How to size the correct dishwasher for your establishment

Just scroll down until you find the appropriate number of covers for your establishment, then across the line to see your choices. Sydney Commercial Kitchens sells all of these models at competitive pricing, Australia wide.

Under bench dishwasher characteristics

Things to look for

When buying or replacing an undercounter dishwasher there are several factors to consider.

- Water Consumption - gone are the days when dishwashers use 7 or more litres per wash cycle, reducing the demand on your hot water service. These days you should expect your dishwasher to use between 2.5 to 3.5 litres per cycle.

- Detergent - the less water the dishwasher uses the less the requirement for detergents, saving you money.

- Power requirements - most under bench dishwashers require 15 amps single phase power supply. If you are replacing an older model dishwasher you will need to check because many only needed 10 amps previously. An electrician will be required to upgrade the power supply.

- Currently dishwashers are required to have a low temperature cutout switch. Until the water has reached the required temperature for the rinse cycle the dishwasher will continue to wash. Some people, rather than employing an electrician, simply cut off the existing 15 amp plug and replace it with a new 10 amp plug. If you do this your dishwasher will never worked properly.

- Dimensions - not all new under bench dishwashers fit under the standard bench top height of 900 mm. This is because there is normally a 50 mm profile edge so your dishwasher should have a height of less than 850 mm. If in doubt check the measurement with your stainless steel provider.

- Drainage - Careful consideration should be given to the plumbing requirement of your premises. Under bench dishwashers come in two styles - gravity drain or drain pump. Many premises are unsuitable for gravity drain dishwashers.

Washtech XU

- Rack size: 500 x 500

- Wash Cycles: 2 mins

- Power: 15 amps

- Water use /cycle: 2.6 Lt

- Pump Drain

- Dimensions: 600 x 650 x 855

Washtech GLV

- Rack size: 450 x 450

- Wash Cycles: 1/2/3 mins

- Power: 15 amps

- Water use /cycle: 2.6 Lt

- Pump Drain

- Dimensions: 535 x 600 x 840

Washtech UD

- Rack size: 500 x 500

- Wash Cycles: 1/2/3 mins

- Power: 15 amps

- Water use /cycle: 2.6 Lt

- Pump Drain

- Dimensions: 570 x 635 x 840

Washtech UL

- Rack size: 500 x 500

- Wash Cycles: 1/2/3 mins

- Power: 15 amps

- Water use /cycle: 2.4 Lt

- Pump Drain

- Dimensions: 600 x 635 x 845

Fagor EVO CO-502 BDD

- Rack size: 500 x 500

- Wash Cycles: 90/120/180 secs

- Power: 15 amps

- Water use /cycle: 2.4 Lt

- Pump Drain

- Dimensions: 600 x 600 x 815

Eswood Smartwash SW500

- Rack size: 500 x 500

- Wash Cycles: 90/120/180 secs

- Power: 15 amps

- Water use /cycle: 2.5 Lt

- Pump Drain

- Dimensions: 575 x 605 x 820

Eswood UC-25

- Rack size: 500 x 500

- Wash Cycles: 60/150 secs

- Power: 15 amps

- Water use /cycle: 3.5 Lt

- Gravity Drain

- Dimensions: 605 x 660 x 870

Eswood UC-25NDP

- Rack size: 500 x 500

- Wash Cycles: 60/150 secs

- Power: 15 amps

- Water use /cycle: 3.5 Lt

- Pump Drain

- Dimensions: 605 x 660 x 870

Hobart ECOMAX 502

- Rack size: 500 x 500

- Wash Cycles: 60/180 secs

- Power: 15 amps

- Water use /cycle: 2.9 Lt

- Pump Drain

- Dimensions: 550 x 600 x 830

Hobart PROFI FX

- Rack size: 500 x 500

- Wash Cycles: 90/180/360 secs

- Power: 15 amps

- Water use /cycle: 2.5 Lt

- Pump Drain

- Dimensions: 600 x 600 x 815

Hobart PREMAX FP

- Rack size: 500 x 500

- Wash Cycles: 90/180/230/360 secs

- Power: 15 amps

- Water use /cycle: 2.5 Lt

- Pump Drain

- Dimensions: 600 x 600 x 815

Comenda RF321

- Rack size: 500 x 500

- Wash Cycle: 120 secs

- Power: 15 amps

- Water use /cycle: 3.2 Lt

- Pump Drain

- Dimensions: 600 x 600 x 820

Comenda LF322

- Rack size: 500 x 500

- Wash Cycles: 120/180 secs

- Power: 15 amps

- Water use /cycle: 3.5 Lt

- Pump Drain

- Dimensions: 600 x 600 x 820

Comenda F4EHRRCD

- Rack size: 500 x 500

- Wash Cycles: 60/100/150/480 secs

- Power: 15 amps

- Water use /cycle: 2.7 Lt

- Pump Drain

- Dimensions: 600 x 600 x 820

Pass through dishwashers

Things to look for

When buying or replacing a pass through dishwasher there are several factors to consider.

- Water Consumption - Look for dishwashers that have a lower water consumption. Once again, the lower the water usage the lower the detergent consumption.

- Wash Pump capacity - The greater the wash pump capacity the greater the ability to wash your dishes

- Power Requirements - Pass through dishwashers are available in both 15 amp single phase and 3 phase. The general rule here is the busier your establishment, the more dishes you need to wash, the greater the need for a fast recovery in the water temperature. The faster the recovery the greater the power requirement.

- Dimensions - pass through dishwashers come in three basic sizes, small, medium and large. These days though there are a number of imported European dishwashers on the Australian market and their sizing differs from the normal. If you are establishing a new premises this is not a problem, but be aware, if you are replacing your existing dishwasher and the sizing is different then you may be up for the cost of alterations to your stainless steel benchwork.

Washtech M1

- Rack Size: 450 x 450

- Wash Cycles: 1/2/3 mins

- Power: 415/50/3+E; 10A

- Water Use/cycle: 2.6 Lt

- Wash Pump Capacity: 210 Lt

- Dimensions: 630 x 650 x 1530

Washtech XP

- Rack Size: 500 x 500

- Wash Cycles: 2 mins

- Power: 240/50/1; 15 amps

- Water Use/cycle: 2.6 Lt

- Wash Pump Capacity: 350 Lt

- Dimensions: 705 x 765 x 1530

Washtech M2

- Rack Size: 500 x 500

- Wash Cycles: 1/2/3 mins

- Power: 415/50/3+E+N; 15 amps

- Water Use/cycle: 2.6 Lt

- Wash Pump Capacity: 350 Lt

- Dimensions: 705 x 765 x 1530

Washtech M2C

- Rack Size: 500 x 500

- Wash Cycles: 1/2/3 mins

- Power: 415/50/3+E+N; 15A

- Heat Recovery Condensor Unit

- Water Use/cycle: 2.6 Lt

- Wash Pump Capacity: 350 Lt

- Dimensions: 705 x 765 x 2040

Washtech AL

- Rack Size: 500 x 500

- Wash Cycles: 1/2/3 mins

- Power: 415/50/3+N+E; 15A; 6kW

- Water Use/cycle: 2.4 Lt

- Wash Pump Capacity: 800L

- Dimensions: 750 x 795 x 1525

Comenda Red Line RC411

- Rack Size: 500 x 500

- Wash Cycles: 120 secs

- Power: 415/50/3N; 7.75kW

- Water Use/cycle: 3.2Lt

- Dimensions: 630 x 745 x 1490

Comenda Blue Line LC700TH

- Rack Size: 500 x 500

- Wash Cycles: 90/120/180/480 secs

- Power: 415/50/3N 6.75kW

- Water Use/cycle: 3.2Lt

- Dimensions: 625 x 740 x 1490

Comenda Platinum Line C800EHRDPRCD

- Rack Size: 500 x 500

- Wash Cycles: 75/120/180/480 secs

- Power: 415/50/3N 9.75kW

- Water Use/cycle: 2.8Lt

- Dimensions: 632 x 765 x 1460

Fagor EVO CO-112BDD

- Rack Size: 500 x 500

- Wash Cycles: 90/120/180 secs

- Power: 415/50/3N; 63A; 11.19 kW

- Water Use/cycle: 2.4Lt

- Wash Pump Capacity: 400 Lt

- Dimensions: 655 x 755 x 1540

Fagor EVO AD-125

- Rack Size: 500 x 500

- Wash Cycles: 90/120/180 secs

- Power: 415/50/3N; 63A; 12 kW

- Water Use/cycle: 2.4Lt

- Wash Pump Capacity: 400 Lt

- Dimensions: 655 x 755 x 1540

Fagor EVO AD-125HRS

- Rack Size: 500 x 500

- Wash Cycles: 55/75/120 secs

- Power: 415/50/3N; 63A; 12.3 kW

- Water Use/cycle: 2.4Lt

- Heat Recovery System

- Wash Pump Capacity: 400 Lt

- Dimensions: 655 x 755 x 2258

Eswood Smartwash SW900

- Rack Size: 500 x 500

- Wash Cycles: 90/120/180 secs

- Power: 415/50/3+E+N; 6.75 kW

- Water Use/cycle: 3.5 Lt

- Wash Pump Capacity: 310 Lt

- Dimensions: 595 x 600 x 1375

Eswood ES25

- Rack Size: 500 x 500

- Wash Cycles: 120 secs

- Power: 240/50/1; 15A; 3.5 kW

- Water Use/cycle: 3.5 Lt

- Wash Pump Capacity: 310 Lt

- Dimensions: 595 x 600 x 1375

Eswood ES25

- Rack Size: 500 x 500

- Wash Cycles: 120 secs

- Power: 240/50/1; 15A; 3.5 kW

- Water Use/cycle: 3.5 Lt

- Wash Pump Capacity: 310 Lt

- Dimensions: 595 x 600 x 1375

Eswood ES32

- Rack Size: 500 x 500

- Wash Cycles: 60/75 secs

- Power: 415/50/3N; 9.5kW

- Water Use/cycle: 3.5 Lt

- Wash Pump Capacity: 400 Lt

- Dimensions: 595 x 600 x 1375

Eswood ES50

- Rack Size: 500 x 500

- Wash Cycles: 60/80/100 secs

- Power: 415/50/3N; 10.3kW

- Water Use/cycle: 4 Lt

- Wash Pump Capacity: 700 Lt

- Dimensions: 640 x 640 x 1445

Hobart ECOMAX 602

- Rack Size: 500 x 500

- Wash Cycles: 75/150 secs

- Power: 240/50/1; 15a; 3.2kW

- Water Use/cycle: 2.9 Lt

- Dimensions: 635 x 742 x 1480

Hobart PROFI AM900

- Rack Size: 500 x 500

- Wash Cycles: 60/90/120 secs

- Power: 415/50/3; 7kW

- Water Use/cycle: 2.9 Lt

- Dimensions: 635 x 742 x 1480

Hobart PROFI AMX

- Rack Size: 500 x 500

- Wash Cycles: 60/90/120 secs

- Power: 415/50/3; 6.19kW

- Water Use/cycle: 2.5 Lt

- Dimensions: 635 x 742 x 1480

Glasswashers

Glass washers, like dishwashers come in all shapes and sizes. When purchasing a new glass washer you would be advised to compare:

- Electrical: your current electrical supply with the requirement of the new machine.

- Water: usage varies between 2.5 - 7.0 litres/cycle. You will need to determine how much hot water you have available through your hot water supply and then match that to the needs of your business.

- Rack size: If the rack size is different to the racks that you currently have and they don't fit inside the new machine it may be an expensive addition to buy more racks and even replace the rack storage system.

Following is a comparison chart of Washtech, Hobart and Eswood, Comenda & Fagor Glass Washers. Sydney Commercial Kitchens sells and recommends all of these excellent products at highly competitive prices, Australia wide.

Washtech XG Economy

- Rack size: 435 x 435

- Wash Cycles: 60 secs

- Power: 15 amps

- Water use/cycle: 1.5 Lt

- Dimensions: 440 x 510 x 775

Washtech GM

- Rack size: 435 x 435

- Wash Cycles: 60/120/180 secs

- Power: 15 amps

- Water use/cycle: 2.0 Lt

- Dimensions: 500 x 555 x 860

Washtech GL

- Rack size: 435 x 435

- Wash Cycles: 60/120/180 secs

- Power: 415/50/3; 15A; 6kW

- Water use/cycle: 2.4 Lt

- Dimensions: 535 x 560 x 835

Washtech UL

- Rack size: 500 x 500

- Wash Cycles: 1/2/3 mins

- Power: 250V; 15A

- Water use /cycle: 2.4 Lt

- Dimensions: 600 x 635 x 845

Comenda Red Line RB215

- Rack size: 400 x 400

- Wash Cycles: 2 min

- Power: 240V; 15A

- Water use/cycle: 2.0 Lt

- Dimensions: 460 x 520 x 780

Comenda Blue Line LB275

- Rack size: 400 x 400

- Wash Cycles: 2 min

- Power: 240V; 15A

- Water use/cycle: 2.0 Lt

- Dimensions: 460 x 520 x 700

Comenda Platinum Line BC3ERCD

- Rack size: 400 x 400

- Wash Cycles: 90/120/180/480 secs

- Power: 240V; 15A; 3.57kW

- Water use/cycle: 1.8 Lt

- Dimensions: 480 x 540 x 850

Eswood Smartwash SW400

- Rack size: 430 X 360

- Wash Cycles: 60/90/120 secs

- Power: 240V; 15A; 3.5kW

- Water use/cycle: 1.9 Lt

- Dimensions: 435 x 530 x 840

Eswood B42G

- Rack size: 400 x 400

- Wash Cycles: 60/150 secs variable

- Power: 15 amps

- Water use/cycle: 2.5 Lt

- Cold Water Rinse: Yes

- Dimensions: 510 x 550 x 870

Hobart ECOMAX 402

- Rack size: 400 x 400

- Wash Cycles: 90/120 secs

- Power: 240V; 15A; 2.9kW

- Water use/cycle: 1.9 Lt

- Dimensions: 460 x 590 x 850

Hobart PROFI GC

- Rack size: 400 x 400

- Wash Cycles: 70/120 secs

- Power: 240V; 15A; 2.9kW

- Water use/cycle: 1.95 Lt

- Dimensions: 460 x 590 x 850

Fagor E-VO CO402 Cold BDD

- Rack size: 400 x 400

- Wash Cycles: 90/120/180 secs

- Power: 240V; 15A; 3.06kW

- Water use/cycle: 2.05 Lt

- Cold water rinse selector

- Dimensions: 470 x 520 x 720

Benefits of Recirculating Glass Washers

These days the best choice for glasswashers is a recirculating style. While the non-recirculating style machines are still currently available it is my opinion that they have a limited shelf life.

- 60 Litres of wash water per cycle versus 4 Litres

- Less water usage 2.5 Litres versus 7.0 Litres per cycle

- Less water heating at the cylinder and machine

- Less detergent/chemical usage

- Better results

- Better hygiene

Operational Cost Savings

Potentially there are significant savings annually by using a recirculating style glass washer over the antiquated non recirculating style.

Glass washer cost savings comparison guide

Savings are based on 320 Days per Year Machine in Use

Annual Cost Difference savings $1,646.32

This calculation is for comparison purposes only.

Ice Makers

Air Cooled

All the ice makers advertised on this website are sold standard as air cooled. You should ensure that the room or area where the ice maker is positioned is well ventilated to the side and rear of the machine. Minimum clearance of 100 mm from the back wall and both sides is required. Water cooled ice machines are also available in most models, please specify when ordering.

Production Capacity

Production capacities specified on the website are based on standard water tempersture of between 10C and 21C ambient temperature.

Production capacities are also based on maximum ambient air temperatures of less than 38 C. For areas with a higher ambient temperature production capacity is reduced.

How to Pick the Right Ice Macine for your Business

1. Restaurants & Cafe's

Number of Covers - Cafe's - Restaurants

30 - ICE 1 - ICE 1

50 - ICE 1- ICE 2

75 - ICE 2 - ICE 3

100 - ICE 3 - ACM105

125 - ACM105 - ACS125

150 - ACS125 - ACS175

200+ - ACS175 - ACS225

300+ - ACS225 - MVH300

2. Hotels & Clubs

Number of Patrons / Busiest Period - Hotels - Clubs

Less than 200 - ACS175 - ACS175

200 - ACS225 - ACS225

300 - MVH300 - MVH300

500 - MVH450 - MVH450

800 - MVH600 - MVH600

1300+ - MVH1000 - MVH1000

3. Nursing Homes & Hospitals

Number of Beds - Nursing Homes - Hospitals

20 - ICE 2 - ICE 2

50 - ICE 3 - ICE 3

90 - ACM105 - ACM105

120 - ACS125 - ACS125

180 - ACS175 - ACS175

200+ - ACS225 - ACS225

Installation Instructions

Coolroom_Installation_Instructions

Deli_Open_Display_Installation_Checklist

Prestige_Deli_Installation_Instructions

Microwave Ovens

One of the most common questions asked by microwave users is what is the difference between commercial & domestic microwave ovens. Here are the key differences that make commercial microwave ovens the best, safest and most cost effective solution for your kitchen.

No Glass Turntables

Commercial ovens do not feature glass turntables that are fiddly and reduce usable cavity space. As all food must rotate in order to heat evenly, larger dishes are often too large to rotate. This glass plate is usually lost or smashed on a regular basis. Commercial ovens feature a flat ceramic base that is easily cleaned and does not limit dish size.

Reliability

Domestic microwave ovens are designed for limited usage. Most domestic microwave ovens are designed for household usage that usually does not exceed about 10 minutes of running time per day. Compare this to a commercial application that may require constant usage for hours each day. Therefore commercial microwave ovens are designed using heavy-duty components that enable a far greater workload over a longer period of time.

Speed

Commercial Microwave Ovens are available in far greater power outputs than domestic microwave ovens. A Bonn CM-1900T has a power output of 1900watts compared to approximately 700 – 900 watts for most domestic ovens. This means busy food outlets can cut heating times by up to 60%. Remember, in fast food customers do not wait! The loss of single impatient customer per day is the cost of the oven after 6-12 months.

Cost

Commercial microwave ovens have a higher initial purchase price compared to domestic microwave ovens. This extra cost is however quickly recouped as domestic ovens in a commercial kitchen will require regular repairs and replacement, along with the inconvenience and disruption this causes. Remember a good quality commercial microwave oven that is well maintained will last 5-10 years. In the same situation a domestic oven may only last 6 months.

Convenience

Commercial microwave ovens feature fully programmable control panels. This means that menu heating times and settings can be programmed into the oven control panel. Heating product is then as simple as pushing a single button. This ensures a fast reliable way to heat product, especially in busy periods. It also ensures a consistent result every time. Domestic ovens require power level and time to be entered along with the start button, time consuming and easy to make mistakes.

Food Safety

All commercial microwave ovens are constructed of stainless steel cavity and cabinet assemblies. Stainless steel offers the best sanitation qualities in a commercial grade kitchen. Stainless steel resists breaking down and is easily cleaned. The same applies to commercial microwave ovens. Most domestic microwave ovens are not of stainless steel construction.

User Safety - Microwave Radiation

Heavy-duty commercial microwave ovens are constructed using far more robust materials and also incorporate greater safety features such as glass lined inner doors, strengthened doors, heavy grade door hinges and improved door safety switch designs. All of this means that as a user in a harsh kitchen environment you have greater protection against microwave radiation compared to a domestic microwave used in the same environment. In a busy kitchen all equipment is exposed to a harsh environment, the microwave included. Using a heavy-duty commercial microwave oven is the best way to protect against possible microwave radiation exposure.

Blast Chillers / Blast Freezers

The advantages of blast chilling

GREATER PROFITS

TIME SAVINGS UP TO 30%

Thanks to the longer shelf life of blast chilled food, it is possible to plan production better and prepare larger quantities of dishes and semi-processed foods in advance, without having to repeat the process every day. All this while always keeping the quality of the served foods high.

SAVINGS ON PURCHASES

Thanks to the long shelf life of shock frozen foods, keeping their original qualities unchanged, it is possible to purchase seasonal ingredients when they are less expensive and of better quality.

WASTE REDUCTION

Blast chilling/freezing increases shelf life of foods, leaving all the time to use the foods prepared in advance and the raw materials, with high reduction of waste.

LESS WEIGHT LOSS

After cooking, food releases moisture by evaporation. Blast chilling immediately after cooking stops evaporation, thereby reducing the loss of water and therefore weight. If the product is sold by weight, revenue can be increased by up to 7%.

WIDER MENU

The longer shelf life of blast chilled foods and semi-finished items makes possible to increase the number of courses offered, without complicating production organization.

QUALITY IMPROVMENT

REDUCTION IN BACTERIAL GROWTH

Bacterial proliferation is very high when food is at a temperature of between +65°C and +10°C. Around +37°C the number of bacteria doubles every 20 minutes. Blast chillers makes possible to “cross” the range of hazardous temperatures quickly, taking the core of the food to +3°C in less than 90 min. This reduces the quantity of bacteria in food after cooking to a minimum, improving their quality, organoleptic properties and safety.

COMPLIANCE WITH HACCP STANDARDS

The blast chiller considerably improves food safety, ensuring full compliance with HACCP standards.